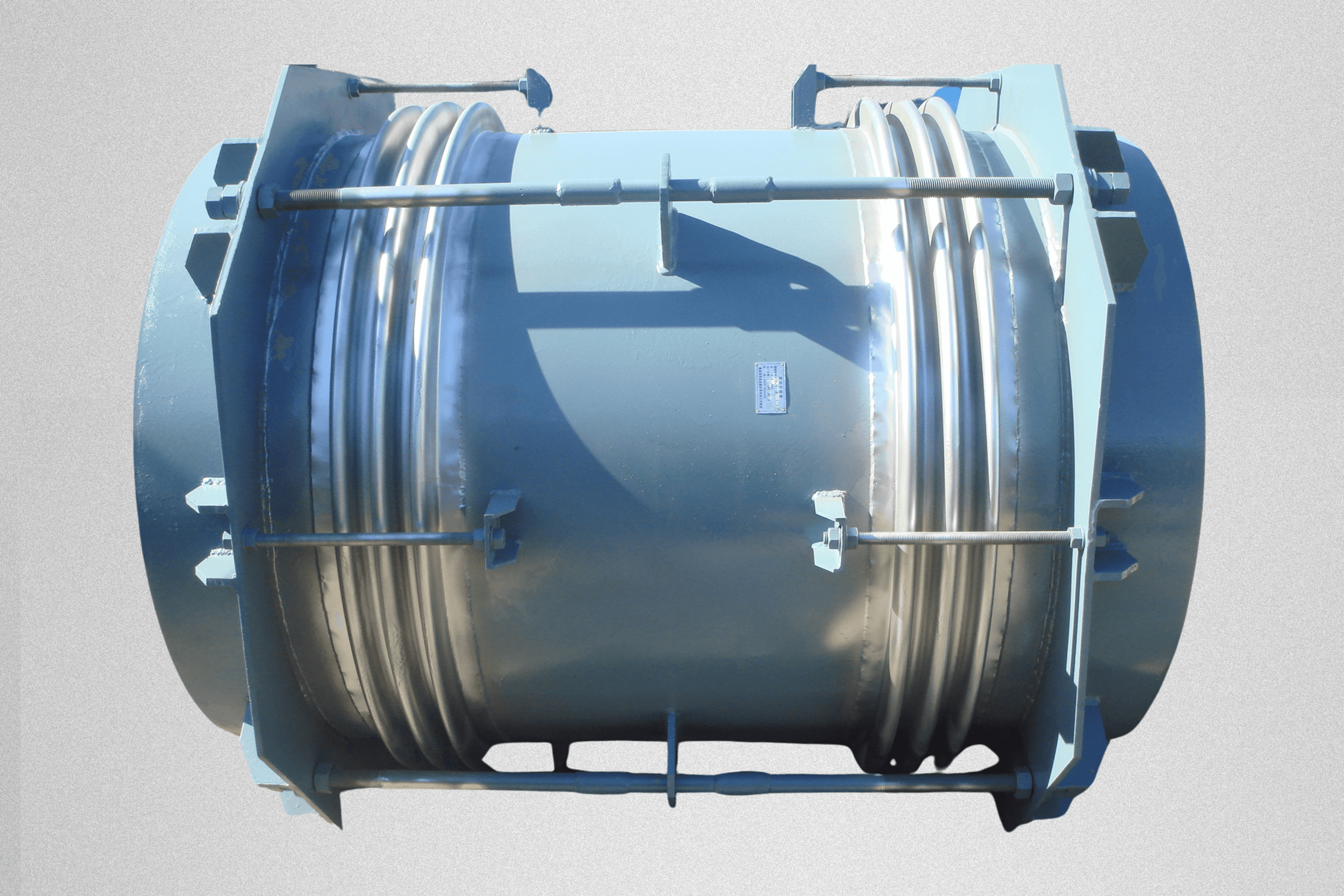

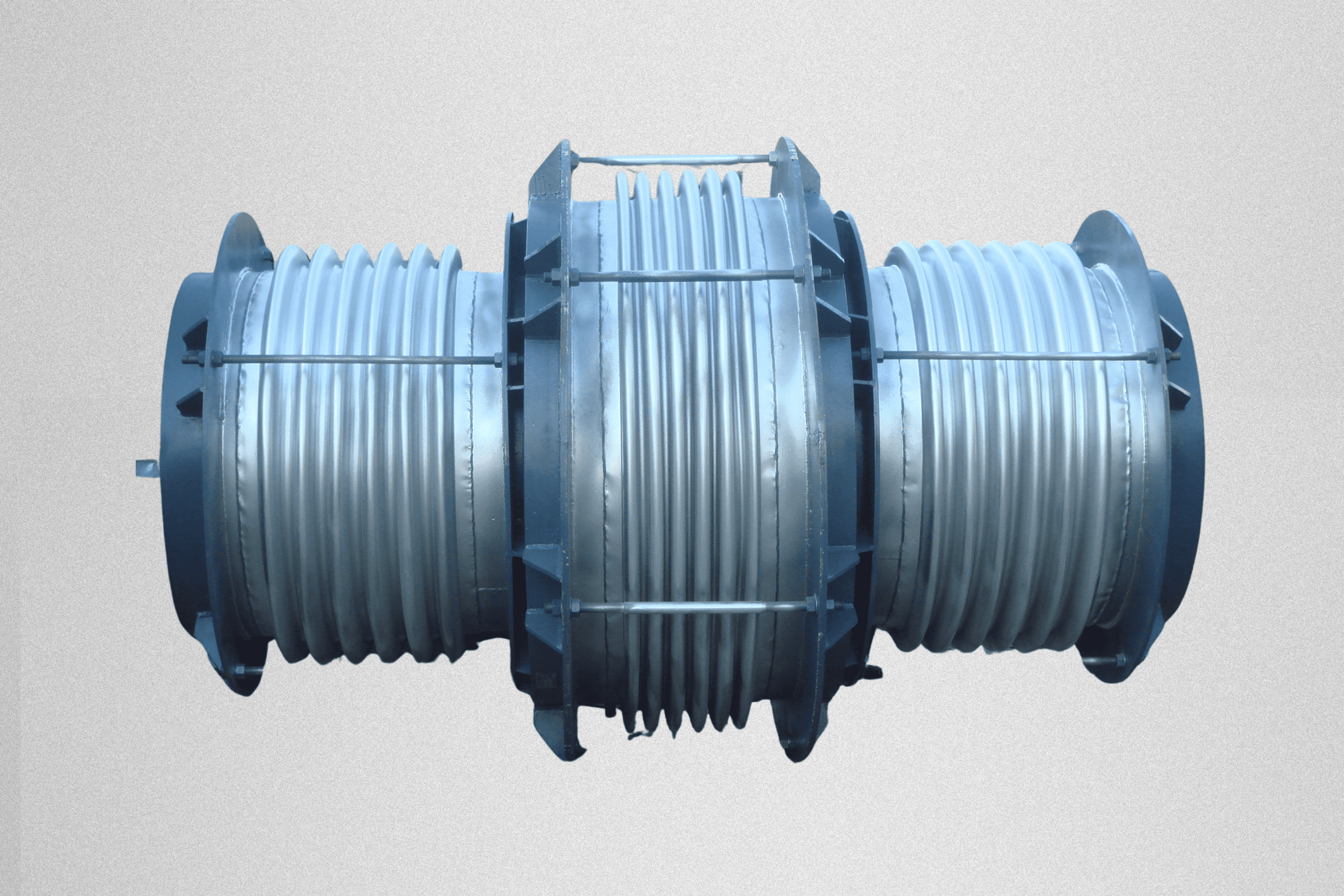

Expansion Joints

We manufacture high-performance expansion joints via advanced forming techniques that ensure exceptional durability, precision, and reliability.

Size Range

Year

The calculation was clear, but their weld integrity was not.

Outstanding expansion joints demand flawless long-seam and attachment welds with zero heat-affected zone weaknesses—any defect initiates premature fatigue failure. fact check this see if ti's good

We made the uncompromising the everyday reality.

Flawless multi-ply forming, zero-defect welding throughout, unmatched fatigue life, and full EJMA compliance delivered as standard—no exceptions, no excuses.

Key Features of Expansion Joints

Decades of proven multi-ply expertise

Multi-ply down to 0.2 mm per ply – highest movement, lowest spring rate

100 % volumetric NDT + automated TIG / plasma / laser welding – zero weld defects

5–10× longer fatigue life than single-ply designs (EJMA 11th Edition verified)

–200 °C to +815 °C with Inconel / Hastelloy, full performance retained

Mechanical expanding, hydraulic forming, and roll forming – all in-house for perfect convolution control

Any type (axial, hinged, gimbal, pressure-balanced) up to DN 3600+ and 150 bar

Full global certifications delivered as standard

Power your critical systems with Hanovix expansion joints – trusted worldwide for zero-failure performance across the toughest industries.

All products manufactured in-house to the same rigorous Hanovix standards of precision, cleanliness and reliability.