Hanovix is a manufacturer engineering precision metal bellows and advanced machinary solutions.

Hanovix is a manufacturer engineering precision metal bellows and advanced machinary solutions.

Hanovix is a manufacturer engineering precision metal bellows and advanced machinary solutions.

/

About us

(01)

/

About us

(01)

/

About us

(01)

We're dedicated to crafting innovated components that shapes the future of manufacturing.

/

25

+

Years of Experience

/

4

Bellows in One Stroke

/

0.05

±

Dimensional Tolerance

/

23

Automated Lines

/

3000

Units Per Day

/

25

+

Years of Experience

/

4

Bellows in One Stroke

/

0.05

±

Dimensional Tolerance

/

23

Automated Lines

/

3000

Units Per Day

/

25

+

Years of Experience

/

4

Bellows in One Stroke

/

0.05

±

Dimensional Tolerance

/

23

Automated Lines

/

3000

Units Per Day

Engineered for reliability and purpose, built to power intelligent automation.

Engineered for reliability and purpose, built to power intelligent automation.

Play Video

© Hanovix Automatic Hydroforming Line

Play Video

© Hanovix Automatic Hydroforming Line

Play Video

© Hanovix Automatic Hydroforming Line

Our Products.

(02)

Our Products.

(02)

Our Products.

(02)

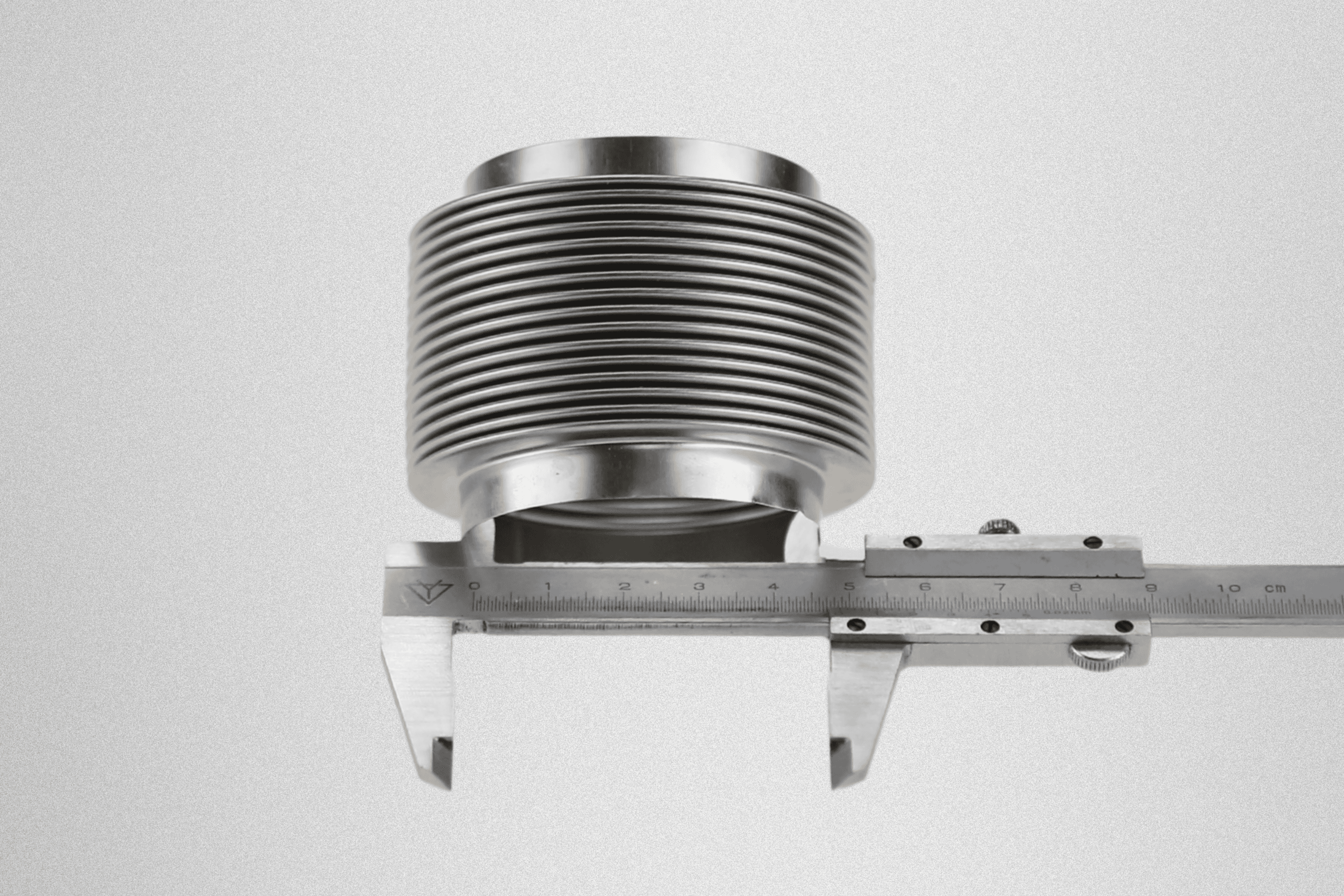

A curated selection of products that reflect our focus on precision and lasting quality.

/

Why us

(03)

/

Why us

(03)

We deliver precision at scale with consistent quantity and competitive cost.

Extensive Tooling Library

Cost-Efficient Customization

International Compliance (EJMA/ASME/CN)

Reliable Lead Time

Global Engineering Support

5/5

Trusted by leaders across industries

"Hanovix delivered precision beyond our expectations. Their attention to detail and consistency across every batch is what truly sets them apart."

Bo Niu

Head of Supplychain

Proven Reliability

Precision-tested bellows built for stable performance and long service life.

Consistent Quality

Every batch meets strict dimensional and performance standards.

Cost Efficiency

Optimized tooling and production methods that reduce total project cost.

Hanovix®

Built with precision.

Driven by purpose, proven by results.

Extensive Tooling Library

Cost-Efficient Customization

International Compliance (EJMA/ASME/CN)

Reliable Lead Time

Global Engineering Support

5/5

Trusted by leaders across industries

"Hanovix delivered precision beyond our expectations. Their attention to detail and consistency across every batch is what truly sets them apart."

Bo Niu

Head of Supplychain

Proven Reliability

Precision-tested bellows built for stable performance and long service life.

Consistent Quality

Every batch meets strict dimensional and performance standards.

Cost Efficiency

Optimized tooling and production methods that reduce total project cost.

Hanovix®

Built with precision.

Driven by purpose, proven by results.

Extensive Tooling Library

Cost-Efficient Customization

International Compliance (EJMA/ASME/CN)

Reliable Lead Time

Global Engineering Support

5/5

Trusted by leaders across industries

"Hanovix delivered precision beyond our expectations. Their attention to detail and consistency across every batch is what truly sets them apart."

Bo Niu

Head of Supplychain

Proven Reliability

Precision-tested bellows built for stable performance and long service life.

Consistent Quality

Every batch meets strict dimensional and performance standards.

Cost Efficiency

Optimized tooling and production methods that reduce total project cost.

Hanovix®

Built with precision.

Driven by purpose, proven by results.

/

Business Scope

(04)

/

Business Scope

(04)

/

Business Scope

(04)

Product Manufacturing

1

We specialize in precision manufacturing, combining advanced forming technologies with strict quality control to ensure reliability and consistency. Our products are built to meet global standards and serve diverse industrial applications requiring durability, performance, and technical accuracy.

Hydro-Formed Metal Bellows

Electroformed Metal Bellows

Edge-Welded Metal Bellows

Metal Bellows Assemblies

Flexible Metal Hoses

Mechanically-Formed Expansion Joints

Machinery Manufacturing

2

We develop complete manufacturing lines engineered for precision, efficiency, and scalability. Our in-house automation, control, and tooling design ensure stable quality, cost effectiveness, and continuous improvement across every stage of production.

Hydroforming Machine

Mechanical Forming Machine

TIG Welding Station

Laser Welding System

CNC Tube Cutting Machine

Automatic Trimming Machine

Academic Research

3

We are currently collaborating with universities on academic research projects focused on advanced manufacturing and materials engineering. We actively seek new partnerships with research institutions and are glad to provide precision components, prototypes, and technical support to aid experimental and applied studies. Our areas of interest include:

Commercial Space Exploration

Solar and CSP Applications

Next-Generation Power Systems

Hybrid Automotive Engines

Advanced Material Research

Cryogenic and Vacuum Technologies

Investment

4

We are actively exploring investment opportunities to expand our manufacturing footprint beyond the Greater China region. Our goal is to establish new facilities that enhance logistics, shorten lead times, and strengthen service capabilities for our international clients. These new operations will allow us to provide localized production and more responsive support across key global markets. Countries include:

Mexico

Turkey

Vietnam

Product Manufacturing

We specialize in precision manufacturing, combining advanced forming technologies with strict quality control to ensure reliability and consistency. Our products are built to meet global standards and serve diverse industrial applications requiring durability, performance, and technical accuracy.

Hydro-Formed Metal Bellows

Electroformed Metal Bellows

Edge-Welded Metal Bellows

Metal Bellows Assemblies

Flexible Metal Hoses

Mechanically-Formed Expansion Joints

Machinery Manufacturing

We develop complete manufacturing lines engineered for precision, efficiency, and scalability. Our in-house automation, control, and tooling design ensure stable quality, cost effectiveness, and continuous improvement across every stage of production.

Hydroforming Machine

Mechanical Forming Machine

TIG Welding Station

Laser Welding System

CNC Tube Cutting Machine

Automatic Trimming Machine

Academic Research

We are currently collaborating with universities on academic research projects focused on advanced manufacturing and materials engineering. We actively seek new partnerships with research institutions and are glad to provide precision components, prototypes, and technical support to aid experimental and applied studies. Our areas of interest include:

Commercial Space Exploration

Solar and CSP Applications

Next-Generation Power Systems

Hybrid Automotive Engines

Advanced Material Research

Cryogenic and Vacuum Technologies

Investment

We are actively exploring investment opportunities to expand our manufacturing footprint beyond the Greater China region. Our goal is to establish new facilities that enhance logistics, shorten lead times, and strengthen service capabilities for our international clients. These new operations will allow us to provide localized production and more responsive support across key global markets. Countries include:

Mexico

Turkey

Vietnam

Product Manufacturing

We specialize in precision manufacturing, combining advanced forming technologies with strict quality control to ensure reliability and consistency. Our products are built to meet global standards and serve diverse industrial applications requiring durability, performance, and technical accuracy.

Hydro-Formed Metal Bellows

Electroformed Metal Bellows

Edge-Welded Metal Bellows

Metal Bellows Assemblies

Flexible Metal Hoses

Mechanically-Formed Expansion Joints

Machinery Manufacturing

We develop complete manufacturing lines engineered for precision, efficiency, and scalability. Our in-house automation, control, and tooling design ensure stable quality, cost effectiveness, and continuous improvement across every stage of production.

Hydroforming Machine

Mechanical Forming Machine

TIG Welding Station

Laser Welding System

CNC Tube Cutting Machine

Automatic Trimming Machine

Academic Research

We are currently collaborating with universities on academic research projects focused on advanced manufacturing and materials engineering. We actively seek new partnerships with research institutions and are glad to provide precision components, prototypes, and technical support to aid experimental and applied studies. Our areas of interest include:

Commercial Space Exploration

Solar and CSP Applications

Next-Generation Power Systems

Hybrid Automotive Engines

Advanced Material Research

Cryogenic and Vacuum Technologies

Investment

We are actively exploring investment opportunities to expand our manufacturing footprint beyond the Greater China region. Our goal is to establish new facilities that enhance logistics, shorten lead times, and strengthen service capabilities for our international clients. These new operations will allow us to provide localized production and more responsive support across key global markets. Countries include:

Mexico

Turkey

Vietnam

/

Process

(05)

/

Process

(05)

/

Process

(05)

Our process is simple, reliable, and transparent.

We believe great manufacturing comes from clarity, collaboration, and consistency.

Confirm Specifications and Design

1

We work closely with clients to confirm all technical details — materials, dimensions, tolerances, and testing standards — ensuring a clear foundation before production begins.

Confirm Specifications and Design

1

We work closely with clients to confirm all technical details — materials, dimensions, tolerances, and testing standards — ensuring a clear foundation before production begins.

Confirm Specifications and Design

1

We work closely with clients to confirm all technical details — materials, dimensions, tolerances, and testing standards — ensuring a clear foundation before production begins.

Production & Quality Control

2

Manufacturing is scheduled through our automated lines, with in-process inspections and final testing performed according to EJMA, ASME, or client-specific requirements.

Production & Quality Control

2

Manufacturing is scheduled through our automated lines, with in-process inspections and final testing performed according to EJMA, ASME, or client-specific requirements.

Production & Quality Control

2

Manufacturing is scheduled through our automated lines, with in-process inspections and final testing performed according to EJMA, ASME, or client-specific requirements.

Packaging & Documentation

3

Every order includes complete inspection reports, certifications, and custom packaging designed to protect components during transit.

Packaging & Documentation

3

Every order includes complete inspection reports, certifications, and custom packaging designed to protect components during transit.

Packaging & Documentation

3

Every order includes complete inspection reports, certifications, and custom packaging designed to protect components during transit.

International Logistics

4

We coordinate export logistics and documentation, supporting air, sea, and express shipping options to ensure timely and reliable delivery worldwide.

International Logistics

4

We coordinate export logistics and documentation, supporting air, sea, and express shipping options to ensure timely and reliable delivery worldwide.

International Logistics

4

We coordinate export logistics and documentation, supporting air, sea, and express shipping options to ensure timely and reliable delivery worldwide.

Quotation & Lead Time

(06)

Quotation & Lead Time

(06)

Quotation & Lead Time

(06)

A clear overview of our manufacturing scope, timelines, and commitment to precision and reliability.

Fits Our Existing Tooling

Requires New Tooling

Shipping Lead Time

Hanovix®

30

45

Business Days

For projects compatible with our existing forming tool library. Ideal for repeat designs or standard dimensions, allowing faster turnaround and reduced setup time while maintaining certified quality and precision.

What's included:

Technical Drawing Confirmation

Quotation & Lead Time Plan

Standard Material Certification

In-Process & Final Inspection

Inspection Summary Report

Standard Packaging & Export Support

Efficient Production Scheduling

Ongoing Communication

Get Quotation in

3 Business Days

Fits Our Existing Tooling

Requires New Tooling

Shipping Lead Time

Hanovix®

30

45

Business Days

For projects compatible with our existing forming tool library. Ideal for repeat designs or standard dimensions, allowing faster turnaround and reduced setup time while maintaining certified quality and precision.

What's included:

Technical Drawing Confirmation

Quotation & Lead Time Plan

Standard Material Certification

In-Process & Final Inspection

Inspection Summary Report

Standard Packaging & Export Support

Efficient Production Scheduling

Ongoing Communication

Get Quotation in

3 Business Days

Fits Our Existing Tooling

Requires New Tooling

Shipping Lead Time

Hanovix®

30

45

Business Days

For projects compatible with our existing forming tool library. Ideal for repeat designs or standard dimensions, allowing faster turnaround and reduced setup time while maintaining certified quality and precision.

What's included:

Technical Drawing Confirmation

Quotation & Lead Time Plan

Standard Material Certification

In-Process & Final Inspection

Inspection Summary Report

Standard Packaging & Export Support

Efficient Production Scheduling

Ongoing Communication

Get Quotation in

3 Business Days

/

FAQs

(08)

/

FAQs

(08)

/

FAQs

(08)

Working with Hanovix

Answers to common questions about our process, services, and how we work.

Hanovix is a privately owned industrial group headquartered in Hong Kong, serving as the parent company of: Qinhuangdao Hengchang Flexible Hoses, established in 2000 in Hebei Province (Tier 3 city, the starting point of the Great Wall, highly focused on industrial development in China), specializing in the production of metal hoses, expansion joints, and metal bellows. Hengchang Bellows Limited (Chengdu), established in 2025 in Sichuan Province (Tier 1 city, southern China, hometown of pandas and hotpot), a new, highly automated facility focusing on hydroformed, electroformed, and edge-welded bellows in small diameters for advanced industries such as energy, semiconductor, and scientific research. The Hanovix team has more than 25 years of experience in precision bellows manufacturing and automation. We have been the machinery providers and technical backbone behind many leading bellows and expansion joint manufacturing companies in China.

To provide an accurate quotation, we typically need your drawing or key parameters, including: Type of bellows or assembly Dimensions (ID, OD, length, and convolution count if known) Material preference (e.g., 316L, 321, Inconel, etc.) Working pressure, temperature, and medium Quantity and testing requirements If you’re unsure, our engineers can assist by reviewing your application and recommending the best configuration.

We manufacture using certified materials such as: Stainless Steels: 304, 316L, 321, 347H Nickel Alloys: Inconel 625, Inconel 718, Hastelloy C276 Copper & Brass: For low-pressure or vacuum applications All materials are traceable and accompanied by mill certificates upon request.

All Hanovix products undergo strict testing per EJMA, ASME, and EN ISO standards. Typical tests include: Pressure and leak testing Fatigue life and cycle testing Dimensional and visual inspection Helium leak test (for vacuum or critical applications) We provide complete inspection documentation and certificates with every shipment.

Our minimum order varies by product type and size. For standard bellows that fit our existing tooling, we can support low-volume or pilot batches. For new tooling or custom geometries, minimum quantities are typically defined to optimize cost efficiency and material utilization. Prototype or R&D projects are also welcome under flexible terms.

Custom tooling developed for client-specific products is owned and maintained by Hanovix, but it remains dedicated exclusively to that client’s design. We store and service all tooling in-house for future orders, ensuring consistent dimensional accuracy and long-term repeatability.

Yes — Hanovix serves clients worldwide through a fully managed export process. We provide: Export packaging and moisture protection Custom documentation and certificates of origin Air, sea, or express shipment coordination Our facilities are located for efficient global logistics, ensuring timely delivery across regions.

The vision of Hanovix is to accelerate the world’s transition to advanced automation and sustainable energy. No. Hanovix is a privately owned enterprise focused exclusively on civil and commercial manufacturing applications. We do not participate in defense or government-sensitive projects. Our goal is to build multi-regional manufacturing and service networks that support diverse clients across global industries. When long-term collaboration or regional support is required, Hanovix is capable of establishing local entities or offices to ensure seamless cooperation, communication, and supply capabilities — including in key markets such as the United States and Europe.

Hanovix is a privately owned industrial group headquartered in Hong Kong, serving as the parent company of: Qinhuangdao Hengchang Flexible Hoses, established in 2000 in Hebei Province (Tier 3 city, the starting point of the Great Wall, highly focused on industrial development in China), specializing in the production of metal hoses, expansion joints, and metal bellows. Hengchang Bellows Limited (Chengdu), established in 2025 in Sichuan Province (Tier 1 city, southern China, hometown of pandas and hotpot), a new, highly automated facility focusing on hydroformed, electroformed, and edge-welded bellows in small diameters for advanced industries such as energy, semiconductor, and scientific research. The Hanovix team has more than 25 years of experience in precision bellows manufacturing and automation. We have been the machinery providers and technical backbone behind many leading bellows and expansion joint manufacturing companies in China.

To provide an accurate quotation, we typically need your drawing or key parameters, including: Type of bellows or assembly Dimensions (ID, OD, length, and convolution count if known) Material preference (e.g., 316L, 321, Inconel, etc.) Working pressure, temperature, and medium Quantity and testing requirements If you’re unsure, our engineers can assist by reviewing your application and recommending the best configuration.

We manufacture using certified materials such as: Stainless Steels: 304, 316L, 321, 347H Nickel Alloys: Inconel 625, Inconel 718, Hastelloy C276 Copper & Brass: For low-pressure or vacuum applications All materials are traceable and accompanied by mill certificates upon request.

All Hanovix products undergo strict testing per EJMA, ASME, and EN ISO standards. Typical tests include: Pressure and leak testing Fatigue life and cycle testing Dimensional and visual inspection Helium leak test (for vacuum or critical applications) We provide complete inspection documentation and certificates with every shipment.

Our minimum order varies by product type and size. For standard bellows that fit our existing tooling, we can support low-volume or pilot batches. For new tooling or custom geometries, minimum quantities are typically defined to optimize cost efficiency and material utilization. Prototype or R&D projects are also welcome under flexible terms.

Custom tooling developed for client-specific products is owned and maintained by Hanovix, but it remains dedicated exclusively to that client’s design. We store and service all tooling in-house for future orders, ensuring consistent dimensional accuracy and long-term repeatability.

Yes — Hanovix serves clients worldwide through a fully managed export process. We provide: Export packaging and moisture protection Custom documentation and certificates of origin Air, sea, or express shipment coordination Our facilities are located for efficient global logistics, ensuring timely delivery across regions.

The vision of Hanovix is to accelerate the world’s transition to advanced automation and sustainable energy. No. Hanovix is a privately owned enterprise focused exclusively on civil and commercial manufacturing applications. We do not participate in defense or government-sensitive projects. Our goal is to build multi-regional manufacturing and service networks that support diverse clients across global industries. When long-term collaboration or regional support is required, Hanovix is capable of establishing local entities or offices to ensure seamless cooperation, communication, and supply capabilities — including in key markets such as the United States and Europe.

Hanovix is a privately owned industrial group headquartered in Hong Kong, serving as the parent company of: Qinhuangdao Hengchang Flexible Hoses, established in 2000 in Hebei Province (Tier 3 city, the starting point of the Great Wall, highly focused on industrial development in China), specializing in the production of metal hoses, expansion joints, and metal bellows. Hengchang Bellows Limited (Chengdu), established in 2025 in Sichuan Province (Tier 1 city, southern China, hometown of pandas and hotpot), a new, highly automated facility focusing on hydroformed, electroformed, and edge-welded bellows in small diameters for advanced industries such as energy, semiconductor, and scientific research. The Hanovix team has more than 25 years of experience in precision bellows manufacturing and automation. We have been the machinery providers and technical backbone behind many leading bellows and expansion joint manufacturing companies in China.

To provide an accurate quotation, we typically need your drawing or key parameters, including: Type of bellows or assembly Dimensions (ID, OD, length, and convolution count if known) Material preference (e.g., 316L, 321, Inconel, etc.) Working pressure, temperature, and medium Quantity and testing requirements If you’re unsure, our engineers can assist by reviewing your application and recommending the best configuration.

We manufacture using certified materials such as: Stainless Steels: 304, 316L, 321, 347H Nickel Alloys: Inconel 625, Inconel 718, Hastelloy C276 Copper & Brass: For low-pressure or vacuum applications All materials are traceable and accompanied by mill certificates upon request.

All Hanovix products undergo strict testing per EJMA, ASME, and EN ISO standards. Typical tests include: Pressure and leak testing Fatigue life and cycle testing Dimensional and visual inspection Helium leak test (for vacuum or critical applications) We provide complete inspection documentation and certificates with every shipment.

Our minimum order varies by product type and size. For standard bellows that fit our existing tooling, we can support low-volume or pilot batches. For new tooling or custom geometries, minimum quantities are typically defined to optimize cost efficiency and material utilization. Prototype or R&D projects are also welcome under flexible terms.

Custom tooling developed for client-specific products is owned and maintained by Hanovix, but it remains dedicated exclusively to that client’s design. We store and service all tooling in-house for future orders, ensuring consistent dimensional accuracy and long-term repeatability.

Yes — Hanovix serves clients worldwide through a fully managed export process. We provide: Export packaging and moisture protection Custom documentation and certificates of origin Air, sea, or express shipment coordination Our facilities are located for efficient global logistics, ensuring timely delivery across regions.

The vision of Hanovix is to accelerate the world’s transition to advanced automation and sustainable energy. No. Hanovix is a privately owned enterprise focused exclusively on civil and commercial manufacturing applications. We do not participate in defense or government-sensitive projects. Our goal is to build multi-regional manufacturing and service networks that support diverse clients across global industries. When long-term collaboration or regional support is required, Hanovix is capable of establishing local entities or offices to ensure seamless cooperation, communication, and supply capabilities — including in key markets such as the United States and Europe.

/

Insights

(09)

/

Insights

(09)

/

Insights

(09)

Latest Updates from Hanovix

Product releases, research, events, and company news