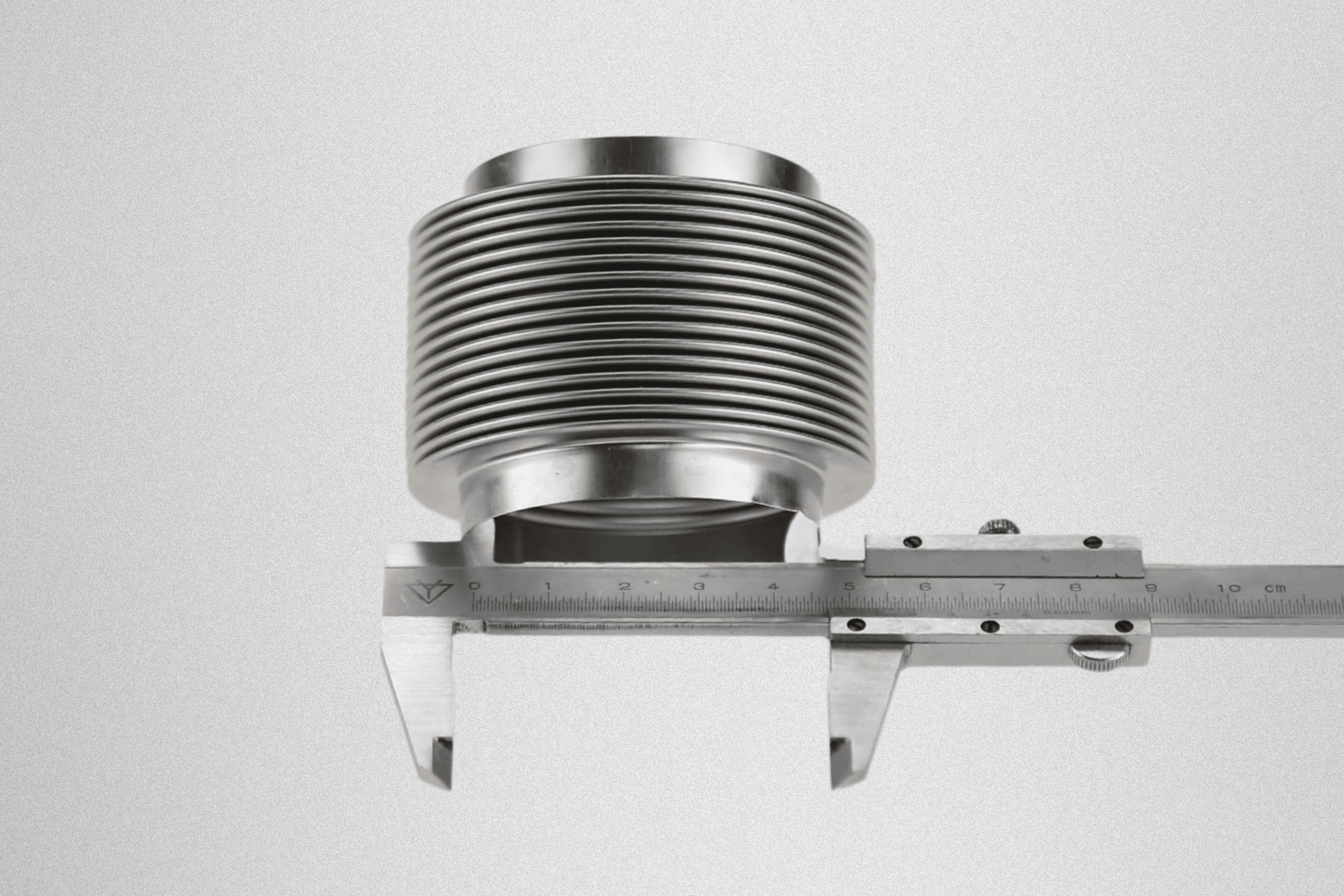

Hydroformed Metal Bellows

We combine automated hydraulic forming and precision tooling to deliver stable geometry and repeatable bellows performance.

Size Range

Year

The process was proven, but consistency at scale was not.

High-quality hydroformed bellows depend on precise pressure control, tooling alignment, and repeatable forming cycles. Manual or semi-automatic operations introduce variability—limiting throughput, geometry stability, and production efficiency.

Automation changed the equation.

We engineered a fully automated hydroforming line that integrates tube feeding, tooling handling, pressure control, and cycle execution into a single closed-loop process. By removing manual die changes and operator-dependent steps, we achieve consistent geometry, stable wall thickness, and dramatically higher production efficiency.

Key Features of Hanovix Hydroformed Bellows

Ultra-small diameter capability (down to DN3)

Automated forming enables stable production of very small-diameter hydroformed bellows, where manual processes typically struggle with consistency.Single-ply and multi-ply bellows structures

Supports both single-layer and multi-layer designs to balance flexibility, pressure capability, and fatigue performance based on application requirements.Clean interlayer control for multi-ply bellows

Controlled forming and handling processes ensure that interlayer interfaces remain clean and intact, avoiding trapped contamination between plies.Stable convolution geometry

Precise pressure control and tooling alignment produce uniform convolution profiles, contributing to predictable mechanical behavior.Broad material compatibility

Applicable to stainless steels, nickel-based alloys (including INCONEL® 625/718), and copper-based materials commonly used in hydroformed bellows.End-to-end production workflow

In-house capability covers forming, intermediate inspection, finishing, and final testing within a unified production system.Quality system–driven manufacturing

Production is governed by a structured quality management system, supporting traceability, process control, and repeatable output.Helium leak testing capability

Finished bellows can be helium leak tested to verify tightness for applications requiring controlled leakage performance.Cost-competitive at production scale

Automation-driven efficiency enables competitive pricing for medium- to high-volume programs without sacrificing process stability or quality control.

Hanovix hydroformed metal bellows combine fully automated forming, multi-ply structural control, and end-to-end quality validation to deliver consistent performance from DN3 micro sizes to mass-production volumes.

All products manufactured in-house to the same rigorous Hanovix standards of precision, cleanliness and reliability.